Information Technology and its applications are far and wide. Aerospace and defense is one massive sector that pioneered the technological development currently utilized across industries.

However, the A&D industry itself sees very little application of IT in its regular operations. Nevertheless, it holds massive potential. It remains firm in standardizing procedures throughout the sector, cutting costs, and streamlining existing manual processes.

IT solutions for aerospace and defense can also quicken certain procedures and lessen the burden on the workforce. Furthermore, it can make performance assessments simpler using data and analytics offered by these IT applications.

The Varied Applications of IT for the Aerospace and Defense Sector

Let us explore 7 underutilized ways IT can propel further growth for A&D firms.

1. Autonomous Robots and Vehicles

Source: NewAtlas

Autonomous vehicles and robotics will become increasingly widespread in the next few years. Aerospace and defense developers already use this solution.

A&D companies will create autonomous military vehicles for harsh weather conditions and the battlefield. The Pentagon, which is frequently mentioned as having the largest defense budget globally, has recently allotted a hefty budget to develop the same.

Crewless and autonomous vehicles, however, pose a challenge for defense software engineers. They must guarantee that the integrated technologies in these cars are reliable in addition to being efficient.

Furthermore, the embedded devices may present a chance for hackers to hack the vehicle’s software system. It is critical to use secure coding methods with a static code analyzer to prevent such a fiasco.

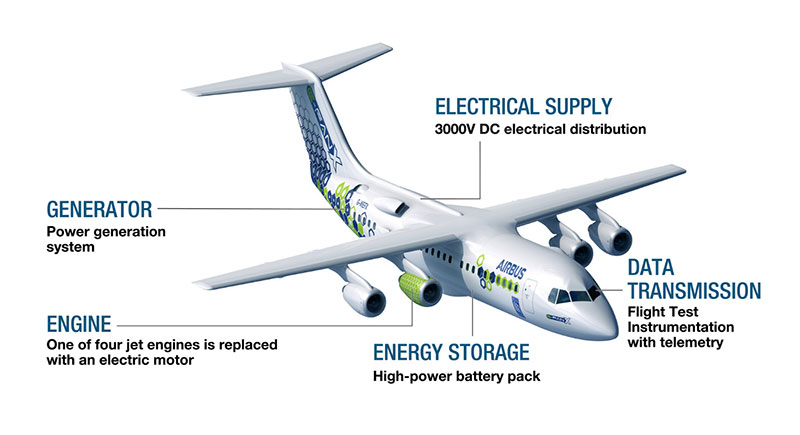

2. Electric and Hybrid Engines

Source: Einfochips

There is a growing need to be more ecologically responsible. It has become a mandatory requirement with mounting carbon emission levels, mainly contributed by the aviation industry. As a result, aerospace engineers have been working on developing electric and hybrid engines.

The development of new engines will still need advanced software and control systems. This guarantees that the machine can produce the required quantity of output for elevation.

Aerospace and defense companies will be required to adhere to functional criteria – IEC 61508 and their internal requirements included.

3. Sensors for Monitoring and Security

Source: PCB

Structural health monitoring, or SHM, is already a standard method of detecting the degradation of processes. It is most commonly used to check the structural integrity of engineering constructions like bridges and buildings.

In the recent decade, aerospace developers have adopted the approach as well. Sensor analysis capabilities have grown in sophistication as technology has improved. Engineers use it to detect structural changes in airplanes, including stress and pressure.

Aerospace and defense firms are also developing more sophisticated sensors that can watch and detect data on land, at sea, in the air, and in space. They also build vital ties that allow this data to be transferred.

Individuals, groups, and governments can utilize these sources of data and transmission systems to fulfill national security, economic, and personal objectives.

4. Digital Threads for Streamlining Solutions for Aerospace and Defense

Source: Aviationweek

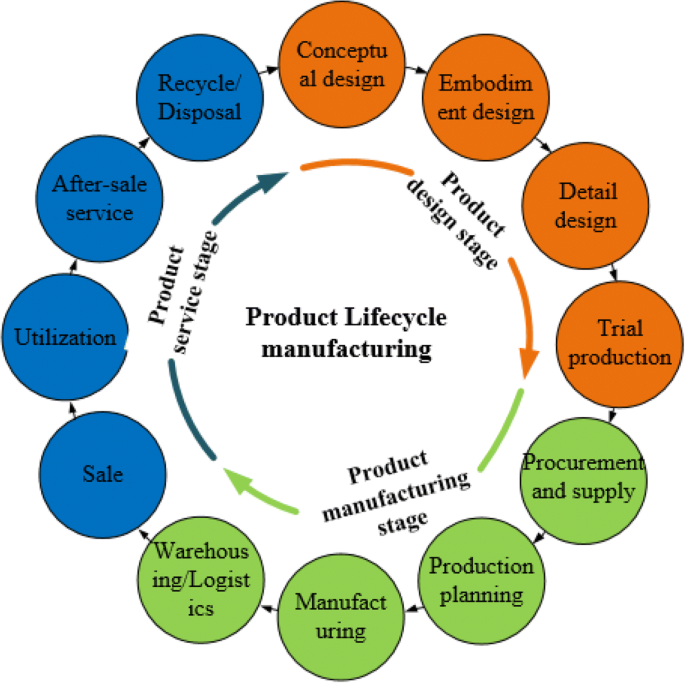

A digital thread links diverse data flows from many stakeholders to provide a comprehensive perspective of a product or solution during its entire lifespan.

A digital thread will enable A&D firms to meet client expectations for quality and timeliness. They encompass the complete product lifetime of an aerospace and defense program, from conceptual design through modeling and simulation to end-of-life maintenance.

Further, this digital thread program provides the workforce with the most up-to-date technologies to:

- Facilitate collaboration

- Produce solutions and products quicker

- Pull data for a project sooner

- Make smarter choices

- Monitor the effects of specific actions in real-time

5. Virtual Simulations

Source: ArmyTechnology

The use of digital threads opens up the possibility for virtual collaboration. In tandem with digital threads, companies can include simulation activities by utilizing a virtual environment and incorporating the outcomes within project lifecycle management.

Virtual simulations are applicable across all disciplines, such as aerodynamics, materials, and propulsion structures. Moreover, they enable the simulation of aspects that impact direct operational expenses, such as performance.

Simulation can become a massive boon to the A&D industry in creating effective, reliable, and valuable solutions for aerospace and defense.

6. Blanket Digitalization of the Production Lifecycle

Aerospace and defense businesses create some of the world’s most advanced technologies. They have spearheaded the use of digital and analytics technology in many of their offerings.

However, digital development now presents a brand-new opportunity for A&D firms to integrate it throughout their product lifecycle. This enables them to create, produce, and service goods faster, more efficiently, and of a higher quality.

Let us examine the impact of Data and Analytics across A&D phases.

-

Research and Development Phase

The automation of A&D procedures has progressed quickly. Nonetheless, the record design for several A&D products continues to remain on paper. Design work also frequently demands manual inspections, at times hampering the quality and enforcing scheduling difficulties.

Reaching the next level of engineering efficiency, speed, and quality, will need companies to emphasize analytics-driven productive output and the digital twins. These are areas that many companies are already exploring.

Yet, there is significant room to accelerate and scale efforts.

In a McKinsey research conducted in collaboration with AIA to examine the digital maturity of the A&D industry, they found that:

- Belatedly digitizing platform designs were outrageously costly, particularly when the companies did not initially create the platforms digitally.

- There is no uniform engineering design language or process in place.

- The requirement for cross-functional teams.

Resolving these issues would only require three things:

- Digitizing processes from conception

- Establishing common standards

- Understanding the requirements of downstream consumers

-

Supply Chain

The supply chain is the most critical cost driver for most A&D companies. Yet, it remains in digital infancy.

This is due to a lack of data, which McKinsey participants also expressed. Almost every company’s data on anything from expenditures to stock levels are so poorly arranged that it is challenging to utilize and make judgments. Despite these obstacles, several organizations are digitizing their distribution networks.

Certain A&D OEMs employ sensors attached to their goods in conjunction with advanced analytical methods to generate real-time estimates of inventory requirements and their storage spots. This helps to reduce costs and improve response times.

-

Production and Manufacturing Phase

Several firms have digitized manufacturing processes and performance management. According to the same McKinsey study, a manufacturer used portable tablets to digitize its technicians’ billing and performance reporting to optimize their work hours. Another manufacturer improved results, expenses, and throughput times by automating its quality operations.

One OEM combines component and skill data to determine the best combination and order of jobs to execute each day. Some Tier-1 suppliers perform large-scale predictive maintenance by attaching sensors to machines and utilizing AI to drive models to improve equipment uptime.

-

Services

While the exact potential will differ across organizations as well as between defense and aerospace, A&D companies can utilize technology to improve their services by:

- Evaluating operational performance to enhance uptime, future designs, and inventory planning.

- Automating pricing and product delivery

- Recognizing the elements that are associated with higher client lifetime value

- Using automated tools to streamline customer assistance and speed up issue response

- Using blockchain to increase transparency throughout the value chain

7. IoT in Aerospace and Defense

In aerospace and defense, the internet of things (IoT) refers to the use of interconnected smart devices with real-time data. The worldwide IoT in the aerospace and defense market was worth $38.67 billion in 2020 and is expected to grow to $145.27 billion by 2030.

IoT’s connectivity and real-time data exchange in A&D enable the aerospace and military industry to achieve maximum operational efficiency of the equipment. This becomes even more feasible thanks to various features such as predictive maintenance, data analytics, and intelligent surveillance systems.

A few of the significant trends in the worldwide IoT in the aerospace and defense market include increased internet penetration and lower costs of sophisticated sensors and controllers. The fleet management segment is the most popular IoT application in the aerospace and defense markets.

Vehicle visualization, theft prevention, and increased productivity associated with vehicle optimization are the primary drivers fueling the expansion of the fleet management aspect in IoT in the A&D sector.

The Road Ahead

As the world becomes more digitally informed, many industries have found a way to grow out of their technology-avoidant approaches. It is the need of the hour to adopt IT solutions for aerospace and defense as well.

Technology such as driverless automobiles and robots have become more prevalent and can help speed up defense processes. Moreover, as sustainability reaches the top of the list of immediate requirements, hybrid and electric engines will become the norm.

Digital threads seamlessly streamline operations and will find growing usage and virtual simulations. Additionally, IoT and sensors can minimize hazards and allow for the secure functioning of A&D firms.

Most importantly, the entire production cycle that continues to seek change can achieve it through an overall digital transformation.

As industry leaders look toward a more streamlined future for the industry, IT solutions can be just the solution for it.