Maybe you have a commercial interest in venturing into the aerospace and defense sector. Or, perhaps find the increased popularity of this industry intriguing. Either way, when you look at the industry reports, you will be clouded with the question – Is aerospace considered manufacturing?

Yes, aerospace has a manufacturing sector that produces parts for spacecraft, missiles, and aircraft. Besides, there are countless job opportunities for technicians and engineers. Thus, making the manufacturing operations an integral part of the industry. The aerospace and defense (A&D) industry employ and adheres to administrative standards while producing commodities.

Continue reading the following section to delve deeper into the A&D manufacturing world.

Why is Aerospace Considered Manufacturing?

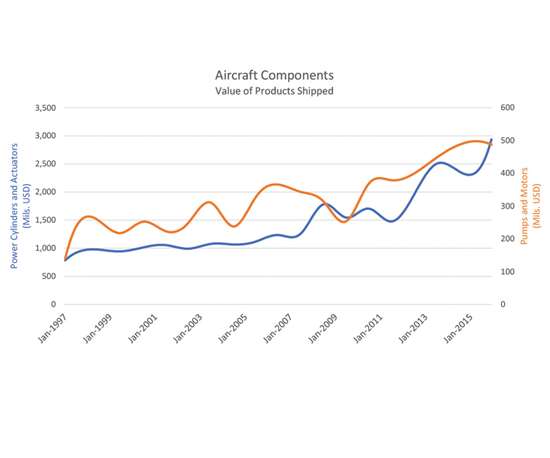

The aerospace and defense industry has been in charge of many things. One of those sub-sectors is manufacturing, which deals with designing, prototyping, producing, and supplying aerospace products.

Moreover, aerospace has a manufacturing entity because a sector of it deals with the production and supply of certain commodities.

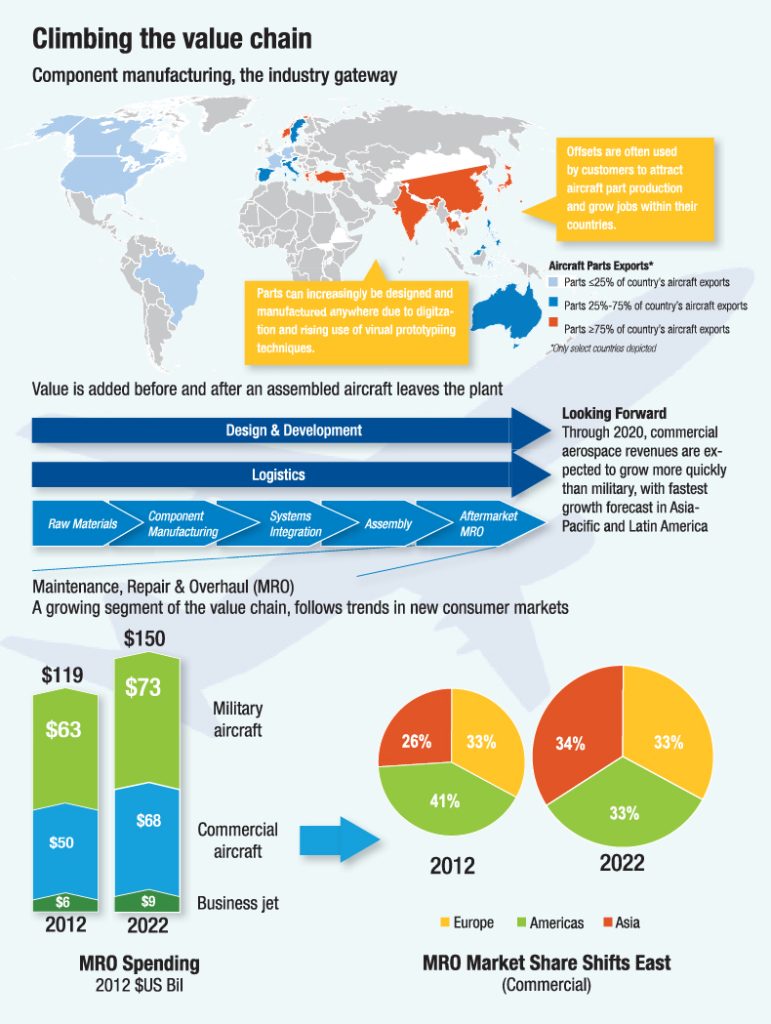

Source: WorldEconomicForum

This industry involves the production of both commercial and defense products. Even though it focuses on creating general aviation equipment, the manufacturing companies must meet high-level quality standards. Besides, the defense units produced must undergo stringent administrative tests before being accepted by the government.

If you’re interested in becoming a part of this sector, you will need certifications or registrations from the United States government.

This quality management ensures that even the entry-level manufacturing process is perfect.

Also Read: A General Overview of Aerospace Industry Standards

The Supply Chain of the A&D Industry

The ecosystem of the A&D manufacturing industry is complex as it involves numerous diverse suppliers. It is, however, a critical component that requires multiple stages of planning and executing. Ideally, an aerospace production facility undergoes the following supply chain process:

- Collection of raw materials from reliable and certified suppliers while maintaining relations

- Extenuation of risks and making changes to the design based on product demands to prevent disruptions

- Incorporation of new aerospace manufacturing technologies that could streamline and optimize the processes

- Utilization of a skilled workforce, qualified and experienced enough to create innovative breakthroughs

These processes are critical for manufacturing, developing, and researching aviation equipment and products.

They must be strategically met to increase the value of the end product. Consequently, your organization must adhere to high-quality standards and spend time improving efficiency by mitigating risks.

Insight Into the A&D Industry’s Product Line

According to the United States Department of Commerce, the aerospace industry is directly and indirectly connected to the manufacturing of commodities. The A&D industry has contributed over $151 billion to the economy as export sales in 2018. Hence, paving the way for aerospace and defense product line growth.

The industry has a broad selection of primary products that require millions of individual parts. At the same time, there are support systems that require maintenance from the aerospace department to operate functionally.

Yet, is aerospace considered manufacturing? Yes, it is! The products that require the manufacturing capacity of the aerospace and defense industry are:

- Military aircrafts

- Commercial and general aviation

- Space systems

- Shipbuilding

- Ground defense

Even with the impact of the pandemic, the AIA workforce remained strong, with over 2 million manufacturers. Besides, the jobs presented by the aerospace and defense industry were 1.4% in the country.

Compliance Requirements for the A&D Manufacturing Industry

As previously stated, the aerospace and defense manufacturing sector requires adherence to quality management systems. Therefore, there are several requirements that an aerospace manufacturing company should meet.

Listed below are the essential guidelines and certifications that a company should meet before manufacturing for the aerospace industry.

AS9100D

Ideally, every company registered as an A&D manufacturer must have a certification with AS9100D because it ensures a proper quality management system for such companies.

The company needs to abide by the international management standards for the defense, space, and aircraft industry. Therefore, the AS9100 registration assures that the produced equipment meets stringent quality, conformity, reliability, and safety standards. Such a company will undergo audits that ensure the facilities’ effectiveness in manufacturing the products.

ITAR

The ITAR acts as a regulatory guideline set by the State Department. It is the International Traffic in Arms Regulations that outline various compliance requirements. The aerospace company must accept the terms and conditions put forward by the ITAR.

This way, the sale and manufacturing process gets supervised and contained by rules. A breach of this agreement would result in the confiscation of the license. The compliance requirements for cross-border trade for technology and items get supervised by ITAR.

AS9102

The AS9102 is the First Article Inspection Report that requires companies to comply with the verification of revised or new equipment. Besides, the AS9102B ensures that the company undergoes a stringent inspection process of all the operational parts.

It helps determine the essential tools, documentation, and processes used to meet the requirements of the aerospace vendor.

ISO

Source: WikimediaCommons

The International Organization for Standardization is an essential consideration for aerospace companies. This certification ensures that the manufacturing process, systems, and documentation meet the standard quality and consistency requirements. The aerospace company must adhere to the ISO standards put forward by the central government.

It is one of the more crucial compliance requirements for manufacturers.

Use of Certified And Quality Equipment

Any aerospace manufacturing vendor must utilize the latest technologies and up-to-date machines or equipment. These include:

- CNC machines

- Multitasking equipment

- Automation like flexible manufacturing systems

Would you like to become a technologically advanced A&D manufacturer? Then, you must comply with ISO, ITAR, and more. At the same time, you can own an advanced machine shop if you utilize high-quality equipment sourced from recent inventions.

Besides, employ high-performing machinists capable of fabricating the perfect equipment. This way, you can access excellent operational capabilities that are cost-effective and reliable.

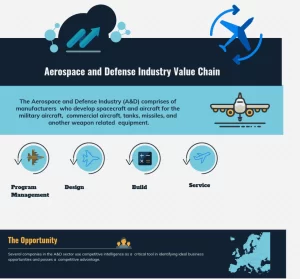

Aerospace Manufacturing for Prototyping And Production in 2022

Source: PredictiveAnalyticsToday

The industry ventured into this new decade with the determination to utilize advanced processes for manufacturing products.

Over the months, the United States government introduced integrated technologies that provide end-to-end development solutions to the industry. Therefore, paving the way for digital, intelligent, and advanced processes masked as powerful technical creations.

As a result, the development and production have brought forth on-demand prototyping processes as mentioned below.

- Aerospace ascending its trajectory

- On-demand and low-volume production process

- Utilization of additive manufacturing

- Use of high-performing materials like Titanium, Inconel, etc.

- Stringent designing, testing, and developing process

- Constant inspection, certifications, and quality control

The A&D industry leverages the expertise of digital manufacturers. Hence, they adhere to stringent compliances to bring forth the manufacturing methods. In turn, discovering powerful technologies geared towards exponential development.

Frequently Asked Questions

1. Is aerospace considered manufacturing?

Yes, the aerospace sector produces parts for various industries like defense, space, and commercial. This department is responsible for manufacturing aircraft, missiles, and spacecraft. Moreover, the industry involves talented technicians who work on the operations while maintaining compliances in the United States.

2. How does aerospace manufacturing work?

Ideally, aerospace manufacturing requires the use of high technology. The industry can produce space vehicles, propulsion units, aircraft engines, missiles, and other products. Besides, the A&D industry gears the manufacturing process towards government work.

3. What are the primary segments of the aerospace and defense industry?

Even though the A&D industry has a few sub-sectors, the primary ones are civil aviation and military aviation. Moreover, the sector transformed over a few years in the United States and brought huge ROI with new technologies. In turn, giving rise to this well-renowned manufacturing industry.

4. What do aerospace manufacturing companies do?

The companies in the United States that fall in this industry prioritize building defense and aerospace-related products. These include ships, weapon systems, spacecraft, aircraft, and more. Such companies would produce and sell these products to the government or other private affiliates.

5. What is the aerospace manufacturing technology program?

The aerospace manufacturing technology program is a course sequence for students aspiring to become aerospace technicians. You can gain multiple skills and knowledge about the industry’s operational capabilities. At the same time, you can master these skills and venture into high-demand avenues like composite fabrication, mechanical assembly, and basic avionics.

The Bottom Line

Without the manufacturing capabilities of this industry, the aerospace sector in the United States would lose its credibility.

The operations would come to a halt since no other industry can manufacture such high-quality products and commodities.

To answer your question – Is aerospace considered manufacturing? Yes, it is a manufacturing sector without which the country’s defense and commercial units would falter in development.

Besides, aerospace manufacturing is crucial as it enables companies to improve quality while increasing opportunities. The tools crafted by mechanical geniuses eventually reduce costs and cut down on inventory while keeping the work rate high.

In 2022, the industry is set to discover new innovative techniques to increase the efficiency of aerospace and defense. So, one has to wait and see how these innovations create an impact.

Also Read: How Artificial Intelligence can enhance the Capabilities of Humans on the Battlefield?