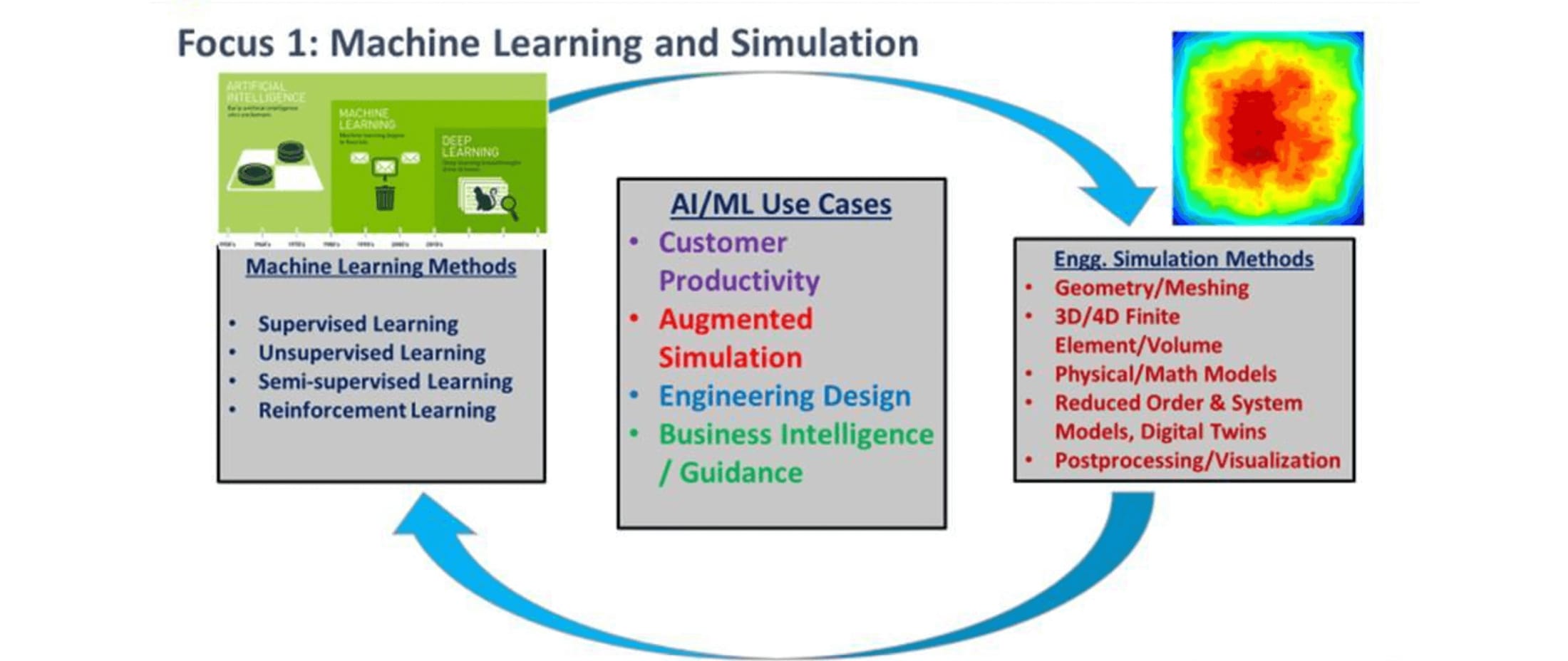

The architectural backbone of modeling and simulation is rapidly evolving to meet customer demand for highly accurate product designs generated with greater speed. Incorporating deep learning — a subset of machine learning and artificial intelligence — enables simulation software to autonomously learn how to solve complex design challenges that result in better products.

Deep learning is ushering in a new era of democratized simulation which will disrupt nearly every industry. It will enable almost anyone — even those with a limited engineering background — to run simulations by offering a simple set of parameters and instructing the software to simulate an object.

Becoming deep learning-enabled within the next year, simulation tools will improve how engineers innovate new products, allowing them to deliver products to market faster than ever before while cutting costs.

Enhancing Productivity and Product Design

When users run a simulation solver, there are approximately 1,000 different parameter settings they must select, ranging from setting the initial condition to the boundary condition to set up the finite element solver. After users make their selections, they run the simulation and the software works optimally.

Here is the problem: engineers need to determine which one of the countless different parameter settings will help run the software most effectively. The simulation will consume a tremendous amount of time if they aren’t able to find the needle in the haystack.

To enhance productivity, deep learning embedded software engines will be trained to monitor and track how engineers use simulation software to solve a specific problem, such as designing the wing of an aircraft. As the deep learning program monitors a sample of a thousand engineers selecting parameter settings, eventually, the deep learning program will perform similarly, automatically determining every setting of the simulation’s solvers. This simplifies the user experience by significantly reducing their workload.

Speeding Product Design

Some software solvers oftentimes take 10,000 hours to run. That means users would be stuck waiting for over a year while the software solves second-order partial differential equations numerically at every mesh point at every finite element. But what if simulation software could become smarter in order to run faster?

By integrating simulation software with deep learning capabilities, the software becomes educated as it is introduced to scenarios that are slightly different from each other. This enables the software to later infer and process simulation using an educated guess to arrive at a solution. There are two approaches for speeding up the simulation, data-driven deep neural networks (DNN), and physics-informed neural networks (PINN).

For example, after a user runs a computational fluid dynamics (CFD) simulation to measure the airflow on top of a sphere, the simulation could also measure the airflow over ten other shapes, such as an oval, square, triangle, rectangle, etc. These data-driven DNN models require a lot of training data to build a model.

For example, after a user runs a computational fluid dynamics (CFD) simulation to measure the airflow on top of a sphere, the simulation could also measure the airflow over ten other shapes, such as an oval, square, triangle, rectangle, etc. These data-driven DNN models require a lot of training data to build a model.

Eventually, users will need to simulate an odd-shaped structure — like a cell phone — which is not one of the ten different geometries that the CFD software was trained on. The software will make an educated guess that the cell phone’s shape is a rectangle and will provide an output similar to that of a rectangle. The physics-informed PINN models do not require much training but rely on the physics models to build the neural networks.

Ultimately, by leveraging the power of deep learning’s inference abilities, simulation software will work much faster. Instead of requiring 10,000 hours to run a simulation on a supercomputer, the solver can run in mere minutes.

Revolutionizing Product Design

Traditionally, product designs are created with a human-in-the-loop. The user generates a computer-aided design (CAD) drawing, then software performs the meshing and solving. This is a time-consuming process.

The generative design takes product design to the next level. Instead of a human-in-the-loop being responsible for creating a CAD drawing, and executing meshing and simulations, deep learning software will quickly create millions of different designs automatically and nominate a few top choices for user consideration. For example, when designing an aircraft, a user could rapidly visualize and inspect the designs offered by the software and then simply select the optimum one for prototyping.

Optimizing Future Product Designs

To monitor the efficiency of everything from field-deployed assets to factory machines, users have traditionally leveraged a digital twin — a virtual prototype of a deployed asset’s complete system — based on a data-driven artificial intelligence/machine learning model. But a digital twin of an asset is not enough. Users need deep learning operational analytics mapped on top of digital twin data to better understand the product performance and drive modeling accuracy. This data can be used to optimize product design of future assets, simulation tools and customer support.

Creating enhanced product designs will also be achieved by optimizing the simulation tool itself through business intelligence and deep learning. For example, a customer that uses a simulation provider’s tool over a period of time could ask the provider to create an enhanced, next-generation, customized version of the tool to solve a specific problem. Receiving a collection of the customer’s simulations and inputting it into a deep learning model, the provider creates the optimized tool which enables the customer to develop improved product designs.

Pushing the Envelope of Ingenuity

Integrating deep learning into simulation software promises major advantages for users. From mirroring human decision making to performing human-like rationalization to integrating digital twin data, this next-generation software will significantly enhance product performance. Deep learning embedded simulation software will soon open the floodgates of simulation design to nearly anyone, speeding and simplifying a product’s path to market.

Prith Banerjee

Prith Banerjee served as a CTO at ABB and Schneider Electric and as a director of HP Labs and Accenture Tech Labs before joining ANSYS as CTO in 2018. He has also started two electronic design automation (EDA) software startups: Accelchip and Binachip. He was listed in the Fast Company list of 100 top business leaders in 2009.